② Simple structure, standardized processing technology, reliable and durable, and cost-effective.

③ Being able to carry axial loads in both radial direction and axial direction, easy to install, low maintenance cost.

② With low friction torque, low noise and low vibration, and low temperature rise even under high-speed working conditions.

③ Low requirement for the minimum load.

② It can carry radial and axial combined loads, and through the combination of multiple sets of single-row bearings or double-row bearings, can also carry bidirectional axial loads.

③ The combination of multiple sets of single-row bearings and double-row bearings has a higher rigidity.

④ These high-precision products ensure the high speed and good operating performance of bearings.

② The optimized needle roller and raceway shape design can provide higher radial loading capacity.

③ High-precision needle roller bearing can have a high operating precision.

② The non-positioning structure can move axially to some extent.

③ The optimized generatrix profile of the roller decreases the edge stress of the contact part between the roller and the raceway, and also reduces the impact of installation alignment and shaft deflection on the overall performance, thus prolonging the service life.

② It has a high radial bearing capacity and some axial bearing capacity.

③ Optimized internal structure design, roller shape and cage structure make the bearing have a long service life.

② Low friction, noise and vibration, and long service life

③ The products assembled can meet the requirements for the most suitable preloading and rigidity.

④ Parts are detachable and interchangeable, which are more convenient for installation, disassembly and maintenance.

② Components are detachable and this is convenient for installation, disassembly and maintenance.

③ Products with ball seat rings can adapt to the impact of misalignment.

② It can provide very high rigidity in a very small axial space.

③ The optimized needle roller and raceway shape design can reduce the edge contact stress, thus having a longer service life.

② Products with axial positioning can bear some axial load.

③ Being able to bear the unbalance loading and skew operation caused due to slight misalignment

④ The optimized outer surface profile can reduce the contact stress with the guide rail and improve the service life of the guide rail.

⑤ The optimized raceway and roller shape can ensure the long service life of the bearing.

② It is easy and convenient to connect and install adjacent machine parts.

③ Strong bearing capacity and being able to bear all kinds of combined loads

② Apply for high rigidity case

③ Run with high precision and is able to offer preload

② It has compact structure

③ The spherical seat hole is a little helpful for the centring of long shaft

④ Large mounted bearings may be structured with split type for convenient installation and maintenance

② It, as surface contact bearing is suitable for high speed and light load condition

③ It can realize smooth, reliable and noiseless operation

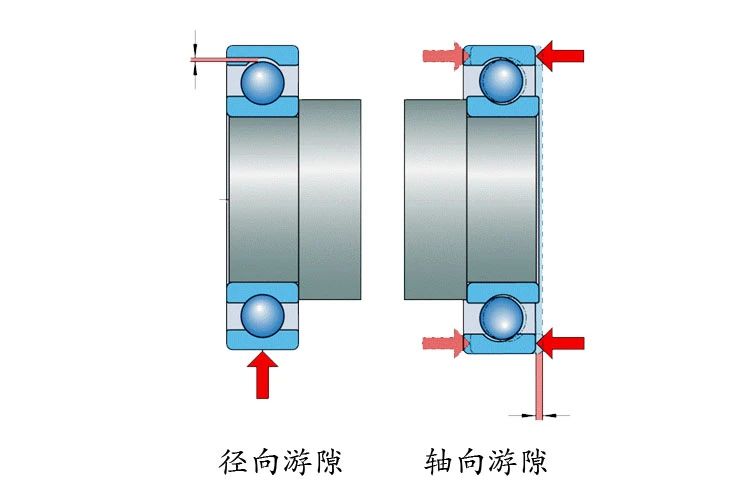

The measurement and adjustment method of the bearing clearance

What is the bearing clearance?

Rolling bearing inner and outer ring and there is a certain gap between rolling body, so can have relative displacement between inner and outer ring, bearing clearance. And measurement methods, depending on the type of bearing clearance can be classified into radial clearance and axial clearance.

Why do you want to measure and adjust the bearing clearance?

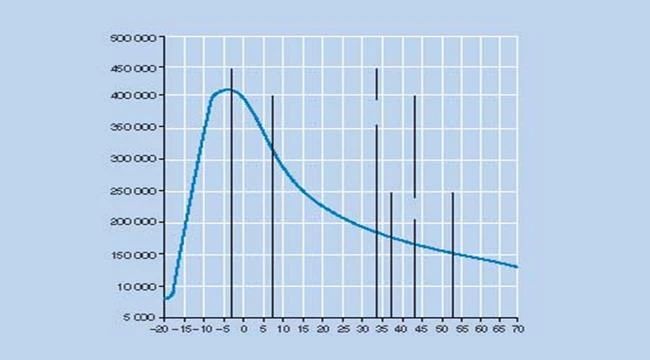

Bearing clearance and its service life is closely linked, under laboratory conditions, the slight negative space, the service life of bearing is highest, but if bearing temperature and installation position not sure, generally recommended to choose large clearance.

Install the bearing clearance, when clearance is too small, rolling bearing temperature, not work properly, can lead to roller jammed; When the clearance is too large, large equipment vibration, will cause the noise of rolling bearings, the appropriate clearance helps the normal work of the rolling bearing.

Bearing clearance measurement methods mainly include: special instrument measuring method, simple measuring method and feeler method. Specific adjustment method: to facilitate the measurement, should be removed before the adjustment on both sides of bearing gland, install the bearing housings, cover up and cover, using a torque wrench fastening bolt bearing four on both sides, tighten in place, after using a feeler gauge measurement, the measured values and standard values of look-up table.

Bearing clearance measurement

Bearing clearance measurement methods mainly include: special instrument measuring method, simple measuring method and feeler method.

Feeler method is the most commonly used method, when the determination of the bearing clearance, bearing vertical platform, pressure bearing outer ring with the hand, keep the inside and outside the ring did not tilt, turn right or left 1/2-1 ring, inner ring roller is stable. Then around the column of any roller respectively into the upper, using a feeler internal clearance.

Adjust bearing clearance

By changing the relative axial or radial raceway position, to adjust the clearance of the bearing is always working in a stable range, so as to improve its working life. The following adjustment method can be used as reference:

(1) the axial clearance adjustment

Fixing bearing inner ring by the shoulder, on either side of the outer ring by preloaded bearing gland, axial clearance of bearing by prestressing force on both sides of the bearing gland and adjustment, considering the bearing clearance decrease caused by fever, bearing the axial certain clearance shall be maintained.

In practice, the axial clearance due to the interference assembly, with little impact on factors such as load, so the installation, take the original clearance of bearing is a standard to adjust.

(2) the radial clearance adjustment

Bearing radial clearance of bearing the stable operation of play a crucial role, for the radial clearance, can refer to GB/T4604-2006 standards, in the actual operation, only in accordance with the standard adjustment bearing radial clearance on the floor.

Specific adjustment method: to facilitate the measurement, should be removed before the adjustment on both sides of bearing gland, install the bearing housings, cover up and cover, using a torque wrench fastening bolt bearing four on both sides, tighten in place, after using a feeler gauge measurement, the measured values and standard values of look-up table.

KIS cora, Leon as a bearing with a German enterprise, pay more attention to product design and quality, ensure effective monitoring products from design to material selection to production in every process. We explore application field representative bearing technology, provide customers high load, high precision, high speed bearing products, innovative technology way bring suitable bearing application solutions for our customers.