② Simple structure, standardized processing technology, reliable and durable, and cost-effective.

③ Being able to carry axial loads in both radial direction and axial direction, easy to install, low maintenance cost.

② With low friction torque, low noise and low vibration, and low temperature rise even under high-speed working conditions.

③ Low requirement for the minimum load.

② It can carry radial and axial combined loads, and through the combination of multiple sets of single-row bearings or double-row bearings, can also carry bidirectional axial loads.

③ The combination of multiple sets of single-row bearings and double-row bearings has a higher rigidity.

④ These high-precision products ensure the high speed and good operating performance of bearings.

② The optimized needle roller and raceway shape design can provide higher radial loading capacity.

③ High-precision needle roller bearing can have a high operating precision.

② The non-positioning structure can move axially to some extent.

③ The optimized generatrix profile of the roller decreases the edge stress of the contact part between the roller and the raceway, and also reduces the impact of installation alignment and shaft deflection on the overall performance, thus prolonging the service life.

② It has a high radial bearing capacity and some axial bearing capacity.

③ Optimized internal structure design, roller shape and cage structure make the bearing have a long service life.

② Low friction, noise and vibration, and long service life

③ The products assembled can meet the requirements for the most suitable preloading and rigidity.

④ Parts are detachable and interchangeable, which are more convenient for installation, disassembly and maintenance.

② Components are detachable and this is convenient for installation, disassembly and maintenance.

③ Products with ball seat rings can adapt to the impact of misalignment.

② It can provide very high rigidity in a very small axial space.

③ The optimized needle roller and raceway shape design can reduce the edge contact stress, thus having a longer service life.

② Products with axial positioning can bear some axial load.

③ Being able to bear the unbalance loading and skew operation caused due to slight misalignment

④ The optimized outer surface profile can reduce the contact stress with the guide rail and improve the service life of the guide rail.

⑤ The optimized raceway and roller shape can ensure the long service life of the bearing.

② It is easy and convenient to connect and install adjacent machine parts.

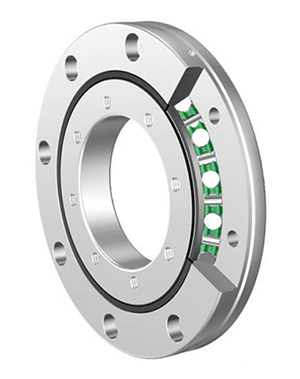

③ Strong bearing capacity and being able to bear all kinds of combined loads

② Apply for high rigidity case

③ Run with high precision and is able to offer preload

② It has compact structure

③ The spherical seat hole is a little helpful for the centring of long shaft

④ Large mounted bearings may be structured with split type for convenient installation and maintenance

② It, as surface contact bearing is suitable for high speed and light load condition

③ It can realize smooth, reliable and noiseless operation

[success] logistics industry bolt roller bearing used in nut loose solution

Customers have a problem

Customers use common specifications of the original bolt type roller bearing with telescopic fork equipment use, in use process found that due to the telescopic fork equipment need to carry from higher levels of radial and axial load, at the same time also has asked for speed, after a period of use, of roller bearing on the nut are found fall off phenomenon, but also a potential risk of shift, not only caused the bearing wear, the stability of the products is greatly reduced. This situation led directly to the transportation equipment fit between the lower precision, using the process is not stable, eventually lead to equipment operation efficiency.

In addition, the customer at the beginning of the bearing assembly, due to factors such as equipment of space, mounting holes and tight fit of bearing installation is very laborious, technicians feedback it is difficult to be pressed.

To this end, the customer puts forward two points on roller bearing requirements:

1, the stability: equipment need to carry large loads of products, in addition to meet the high-efficient use process, the equipment is safe, stable and continuous service, determines the efficiency of production.

2, easy to install: logistics equipment as an important part of the rapid development of industrial automation equipment, to undertake a role, bearing as part of the logistics transmission output, easy installation, no maintenance became the technicians concerned topic.

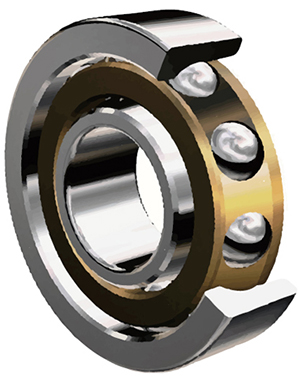

Bolt type roller bearing

KIS to provide solutions

According to the customer's situation reflects, bearing KIS, relying on rich technical experience given alternatives, it is recommended to use with self-locking nut bolt type roller bearing products - KRV16 / KRV22 series, resolve customer in the case of bearing nut off in use process, and combined with easy installation, maintenance free product requirements, added to the bearing of special chamfering and fixed step, facilitate the customer easily installed in equipment debugging phase tests, and put into use.

Bolt type roller bearing using schematic diagram

Customer feedback

After the test, the customer found that the new scheme can effectively solve the problem of the nut off, the service life of the bearing also has improved; Technical personnel at the same time feedback is much more convenient than before when installation, greatly save the operation process, reduce the difficulty coefficient of front-line staff work.

KIS cora, roller bearing

Bolt type roller bearing has the characteristics of high radial load and axial load, its thick outer walls designed to help reduce the deformation and bending; At the same time, the use is easy to wear, easy to fall off. KIS considering the logistics transportation equipment need to ensure that materials such as fast and efficient, safe and reliable in the process of transportation demand, proposed the customized solution, change the products according to the original design, help enhance customer productivity and reliability of the transportation equipment, meet the demand of the continuous growth of the logistics industry on the effectiveness.