产品中心

PRODUCT

CENTER

Deep groove ball bearing

LEARN MORE

![Deep groove ball bearing]()

① With low friction torque, optimized by low vibration and low noise, and suitable for high-speed operation.

② Simple structure, standardized processing technology, reliable and durable, and cost-effective.

③ Being able to carry axial loads in both radial direction and axial direction, easy to install, low maintenance cost.

② Simple structure, standardized processing technology, reliable and durable, and cost-effective.

③ Being able to carry axial loads in both radial direction and axial direction, easy to install, low maintenance cost.

Self-aligning ball bearing

![Self-aligning ball bearing]()

① Having the ability of self-aligning, being able to bear not only the dynamic misalignment caused by shaft deflection, but also the static misalignment caused due to machining or installation.

② With low friction torque, low noise and low vibration, and low temperature rise even under high-speed working conditions.

③ Low requirement for the minimum load.

LEARN MORE

② With low friction torque, low noise and low vibration, and low temperature rise even under high-speed working conditions.

③ Low requirement for the minimum load.

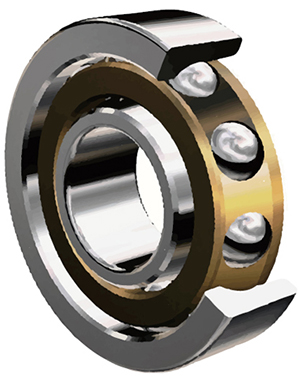

Angular contact ball bearing

LEARN MORE

![Angular contact ball bearing]()

① Higher bearing capacity

② It can carry radial and axial combined loads, and through the combination of multiple sets of single-row bearings or double-row bearings, can also carry bidirectional axial loads.

③ The combination of multiple sets of single-row bearings and double-row bearings has a higher rigidity.

④ These high-precision products ensure the high speed and good operating performance of bearings.

② It can carry radial and axial combined loads, and through the combination of multiple sets of single-row bearings or double-row bearings, can also carry bidirectional axial loads.

③ The combination of multiple sets of single-row bearings and double-row bearings has a higher rigidity.

④ These high-precision products ensure the high speed and good operating performance of bearings.

Needle bearing

LEARN MORE

![Needle bearing]()

① With a small radial section, it is suitable for very small installation space of bearing and bearing pedestal.

② The optimized needle roller and raceway shape design can provide higher radial loading capacity.

③ High-precision needle roller bearing can have a high operating precision.

② The optimized needle roller and raceway shape design can provide higher radial loading capacity.

③ High-precision needle roller bearing can have a high operating precision.

Cylindrical roller bearing

LEARN MORE

![Cylindrical roller bearing]()

① Good rigidity and high radial load bearing capacity

② The non-positioning structure can move axially to some extent.

③ The optimized generatrix profile of the roller decreases the edge stress of the contact part between the roller and the raceway, and also reduces the impact of installation alignment and shaft deflection on the overall performance, thus prolonging the service life.

② The non-positioning structure can move axially to some extent.

③ The optimized generatrix profile of the roller decreases the edge stress of the contact part between the roller and the raceway, and also reduces the impact of installation alignment and shaft deflection on the overall performance, thus prolonging the service life.

Self-aligning roller bearing

![Self-aligning roller bearing]()

① With self-aligning function, it can bear not only the dynamic misalignment caused by shaft deflection, but also the static misalignment caused due to machining or installation.

② It has a high radial bearing capacity and some axial bearing capacity.

③ Optimized internal structure design, roller shape and cage structure make the bearing have a long service life.

LEARN MORE

② It has a high radial bearing capacity and some axial bearing capacity.

③ Optimized internal structure design, roller shape and cage structure make the bearing have a long service life.

Tapered roller bearing

LEARN MORE

![Tapered roller bearing]()

① Being able to bear combined axial and radial loads

② Low friction, noise and vibration, and long service life

③ The products assembled can meet the requirements for the most suitable preloading and rigidity.

④ Parts are detachable and interchangeable, which are more convenient for installation, disassembly and maintenance.

② Low friction, noise and vibration, and long service life

③ The products assembled can meet the requirements for the most suitable preloading and rigidity.

④ Parts are detachable and interchangeable, which are more convenient for installation, disassembly and maintenance.

Thrust ball bearing

LEARN MORE

![Thrust ball bearing]()

① It can bear axial load.

② Components are detachable and this is convenient for installation, disassembly and maintenance.

③ Products with ball seat rings can adapt to the impact of misalignment.

② Components are detachable and this is convenient for installation, disassembly and maintenance.

③ Products with ball seat rings can adapt to the impact of misalignment.

Thrust roller bearing

![Thrust roller bearing]()

① Based on the optimized cage design, it can reliably fix and guide more needle rollers and provide high bearing capacity.

② It can provide very high rigidity in a very small axial space.

③ The optimized needle roller and raceway shape design can reduce the edge contact stress, thus having a longer service life.

LEARN MORE

② It can provide very high rigidity in a very small axial space.

③ The optimized needle roller and raceway shape design can reduce the edge contact stress, thus having a longer service life.

Roller bearing

![Roller bearing]()

① High radial bearing capacity

② Products with axial positioning can bear some axial load.

③ Being able to bear the unbalance loading and skew operation caused due to slight misalignment

④ The optimized outer surface profile can reduce the contact stress with the guide rail and improve the service life of the guide rail.

⑤ The optimized raceway and roller shape can ensure the long service life of the bearing.

LEARN MORE

② Products with axial positioning can bear some axial load.

③ Being able to bear the unbalance loading and skew operation caused due to slight misalignment

④ The optimized outer surface profile can reduce the contact stress with the guide rail and improve the service life of the guide rail.

⑤ The optimized raceway and roller shape can ensure the long service life of the bearing.

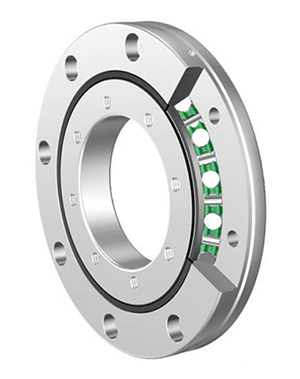

Turntable bearing

LEARN MORE

![Turntable bearing]()

① Unit structure, compact host structure, optimized power transmission

② It is easy and convenient to connect and install adjacent machine parts.

③ Strong bearing capacity and being able to bear all kinds of combined loads

② It is easy and convenient to connect and install adjacent machine parts.

③ Strong bearing capacity and being able to bear all kinds of combined loads

Cross roller bearing

![Cross roller bearing]()

① It can bear axial force in both directions, radial force, upsetting moment and combined loads.

② Apply for high rigidity case

③ Run with high precision and is able to offer preload

LEARN MORE

② Apply for high rigidity case

③ Run with high precision and is able to offer preload

Bearing seat (mounted bearing)

![Bearing seat (mounted bearing)]()

① It can bear combined axial and radial loads

② It has compact structure

③ The spherical seat hole is a little helpful for the centring of long shaft

④ Large mounted bearings may be structured with split type for convenient installation and maintenance

LEARN MORE

② It has compact structure

③ The spherical seat hole is a little helpful for the centring of long shaft

④ Large mounted bearings may be structured with split type for convenient installation and maintenance

Sliding bearing

LEARN MORE

![Sliding bearing]()

① It has large load and bearing capacity, and can bear combined axial and radial loads

② It, as surface contact bearing is suitable for high speed and light load condition

③ It can realize smooth, reliable and noiseless operation

② It, as surface contact bearing is suitable for high speed and light load condition

③ It can realize smooth, reliable and noiseless operation

Packaging machinery

"The packaging process covers filling, wrapping, sealing, etc. The operation of packaging machinery helps introducing products to the circulation market successfully, and the technological innovation of the industry also greatly improves the production efficiency, not only effectively avoiding dust hazards, raw material stimulation, environmental pollution, etc., but also promoting the synchronous development of related processes.

KIS packaging machinery solution aims at accelerating productivity, reducing labor intensity, continuously ensuring good operation rate of equipment and cutting down packaging costs to realize energy-saving goals."

KIS packaging machinery solution aims at accelerating productivity, reducing labor intensity, continuously ensuring good operation rate of equipment and cutting down packaging costs to realize energy-saving goals."